Mẹo nhỏ:Để tìm kiếm chính xác các bài viết của MzEngineer.org, hãy search trên Google với cú pháp: "Từ khóa" + "MzEngineer".(Ví dụ: học cad mzengineer) -> Tìm kiếm ngay

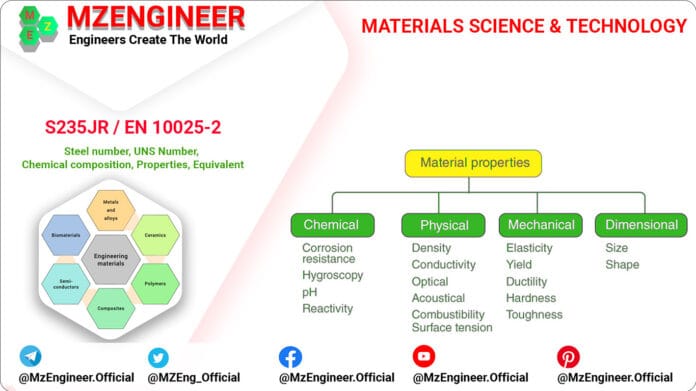

General Data

| Material | S235JR |

| UNS No. / Steel No. | 1.0038 |

| Standard | EN 10250-2:2000 steel S235JRG2 also named 1.0038 |

| Group | Non-alloy quality structural steel According EN 10250-2:2000 steel S235JRG2 also named 1.0038 |

| SubGroup | EN 10025-2: 2004 Hot rolled products of structural steels. Technical delivery conditions for non-alloy structural steels |

| Equivalent grades: | Go here |

Chemical composition

Mechanical properties

Equivalent grades

| European old EN | EU | USA | JAPAN | Germany | China | England | International | India | Italy | Russia | France | Spain | Sweden | Austria | Norway | Viet Nam | Portugal | Belgium | Canada |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| EN | EN | ASTM | JIS | DIN, WNr | GB | BS | ISO | IS | UNI | GOST | AFNOR | UNE | SS | ONORM | NS | TCVN | NP | NBN | HG |

Heat Treatment

Other Properties

Information

Mechanical properties

- ReH Minimum yield strength / Mindestwert der oberen Streckgrenze / Limite d elasticite minimale

- Rm Tensile strength / Zugfestigkeit / Resistance a la traction

- A Minimum elongation / Mindestwert der Bruchdehnung / Allongement minimal

- J Notch impact test / Kerbschlagbiegeversuch / Essai de flexion par choc

- +A Soft annealed

- +AC Annealed to achieve spheroidization of the carbides

- +AR As rolled

- +AT Solution annealed

- +C Cold drawn / hard

- +CR Cold rolled

- +FP Treated to ferrite-pearlite structure and hardness range

- +I Isothermal annealing

- +LC Cold drawn / soft

- +M Thermo mechanical rolling

- +N Normalized

- +NT Normalized and tempered

- +P Precipitation hardened

- +PE Peeled

- +QA Air quenched and tempered

- +QL Liquid quenched and tempered

- +QT Quenched and tempered

- +S Treated to improve shearability

- +SH As rolled and turned

- +SR Cold drawn and stress relieved

- +T Tempered

- +TH Treated to hardness range

- +WW Warm worked

- +U Untreated

Heat treatment conditions

- +A Soft annealed

- +AC Annealed to achieve spheroidization of the carbides

- +AR As rolled

- +AT Solution annealed

- +C Cold drawn / hard

- +CR Cold rolled

- +FP Treated to ferrite-pearlite structure and hardness range

- +I Isothermal annealing

- +LC Cold drawn / soft

- +M Thermo mechanical rolling

- +N Normalized

- +NT Normalized and tempered